Introduction to V-Deck

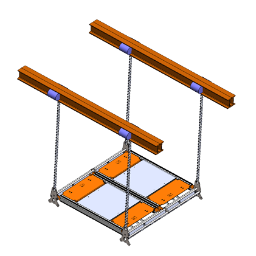

The V-Deck System is based upon high tensile trusses supported off Grade10 steel chains and attached to the structure by high tensile steel locking clamps.

V-Deck is a fully scaffolding compatible modular suspended work platform which delivers game changing metrics compared to scaffolding.

Compared to scaffolding, the V-Deck has delivered up to:

- 88% Time Saving

- 93% Lighter

- 75% Less Volume

- 100% lesser Contact Points

The V-Deck™ is a modular temporary work platform that provides a strong and stable platform for underdeck works. It can be used for large or small work areas dependent upon the customer requirements. The V-Deck™ System is based upon high tensile steel V-Trusses™ which are supported off Grade 10 steel V Chains™ and attached to the structure by high tensile steel locking V-Clamps™.

The 100% marine grade aluminium V-Decks™ latch on to the V-Truss™ forming a continuous work platform. All the component parts are manufactured in the U.K. to BS or EN standards. The Safety Factor is a standard at a minimum of 3:1 for all components. The components to the V-Deck™ System meets the following standards:

- BS EN1004:2004 Class 4

- UDL Max 5kN/m²

Some Features:

The V-Deck™ is fully compatible with all types of scaffolding. Standard scaffolding handrails, toe boards and access towers cab be easily used as the system is fully compatible with all scaffolding types.

- Scaffold boards are used for infill where obstructions dictate.

- The V-Clamps™ can be moved sequentially while the platform is in situ meaning that there are no contact points when the system has been removed. This is particularly beneficial for coatings projects resulting in a top-quality coatings finish.

- The V-Deck™ has a low self-weight which reduces the imposed load on the structure to 25- 35kg/m².

- The V-Deck™ has a low profile of 120mm which means that it can easily be designed to take winds of 50m/s or 112mph. Higher wind speeds can be engineered if required.

- The average install rate from is 50m² per day for a 4-person team. Some experienced teams achieve over 80m2 per day.

- The V-Deck™ can be stepped, lifted, lowered and angled while the platform is in situ in order to overcome obstacles and to provide the exact height required for the works.

- You can build the system multi-directionally as the system can punch out at 90° angles and build out from there. This means that the V-Deck™ provides an easily erected platform for structures with curves like jetties and bridges. It also means that the system can follow the 90° angles of pipework under structures.

- The maximum span for the V-Deck™ is 6m from suspension point to suspension point.

- The maximum UDL is 5kN/m².

- Up to three levels of V-Deck™ may be suspended from anchor points.

- Work areas include, Bridges; Jetties; Pipe racks; Pipe bridges; Offshore helidecks and offshore under decks.