Tackling Challenges in Cable Installation Across Metro Lines

Installing cables above metro tracks is a complex task, requiring a flexible and efficient solution to overcome challenges posed by variable track gauges and limited overhead space. The solution must ensure uninterrupted metro services while maintaining safety and operational efficiency.

A leading metro contractor faced these challenges while laying cables with varying gauges across a metro line. They needed a versatile platform to cover the entire track, accommodate height constraints, and streamline operations without disrupting ongoing metro services.

The Challenge: Safety and Efficiency in a Constrained Environment

The client encountered the following issues during their project:

1. Variable Track Gauges: The track spaces varied, requiring a platform that could adapt to multiple dimensions without frequent modifications.

2. Overhead Space Constraints: Limited vertical clearance caused by beams made it difficult to safely install cables.

3. Continuous Operations: The solution had to facilitate work across the entire track without disrupting metro services or requiring excessive downtime.

The client needed a tailored approach to address these specific challenges while ensuring safety, efficiency, and operational continuity.

The Solution: Y Equipment Services’ Custom Bridge and Trolley Setup

To meet the client’s unique requirements, Y Equipment Services designed an innovative bridge and trolley system with features that ensured flexibility, efficiency, and safety.

Key Features of the Solution:

Custom Bridge:

• Enabled full coverage across the track, eliminating the need for multiple scaffold structures.

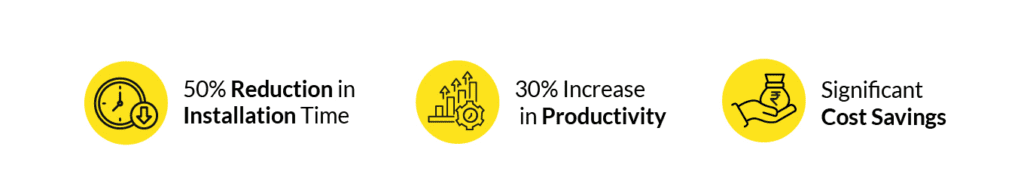

• Provided a continuous work platform for multiple workers, reducing installation time by 50% and increasing productivity by 30%.

Multipurpose Metro Trolley:

• Designed for smooth movement across varying track dimensions without dismantling.

• Allowed seamless adjustments, significantly reducing downtime and ensuring project continuity.

Specialized Frame Combination:

• Enabled quick height adjustments to navigate overhead beam constraints.

• Minimized delays and eliminated the need for frequent dismantling, ensuring a streamlined and efficient workflow.

The Impact: Faster, Safer, and More Cost-Effective Operations

Y Equipment Services’ innovative solution delivered exceptional results for the client:

✅ 50% Reduction in Installation Time: The continuous platform allowed workers to complete the project in half the expected time.

✅ 30% Increase in Productivity: The streamlined design enabled multiple workers to collaborate effectively, improving overall output.

✅ Adaptability to Track Gauges: The trolley’s flexible design ensured smooth transitions across different track widths, eliminating downtime.

✅ Efficient Height Management: The specialized frame allowed swift height adjustments, overcoming beam constraints without delays.

✅ Significant Cost Savings: By finishing the project ahead of schedule, the client saved ₹1,500 per worker per day for 10 workers, achieving substantial labor cost savings.

Conclusion: Revolutionizing Cable Installation Across Metro Tracks

Y Equipment Services’ custom bridge and trolley system provided the client with a time-efficient, cost-effective, and safety-first solution for their cable installation needs. By addressing complex challenges with innovative engineering, the solution exceeded client expectations, delivering high ROI and reinforcing Y Equipment Services’ position as a leader in work-at-height solutions.